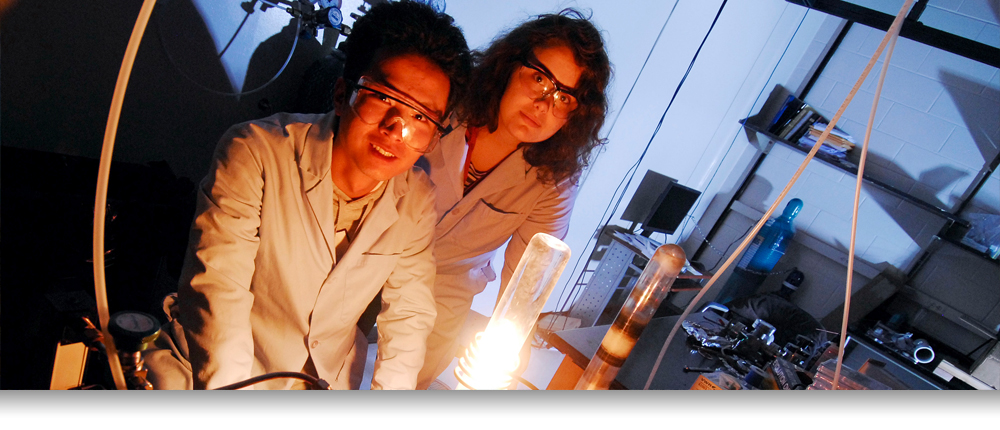

Currently the most promising, readily accessible and inexpensive approach to manufacture graphene is for high quality graphene to be deposited onto copper foil through a process known as chemical vapor deposition, or CVD.

Sapporo Molecular Layered Carbon are one of the lead companies globally in the development of this relatively new technique for the manufacture of graphene and we are seeing very high quality materials with excellent device characteristics being produced. This production process is still being refined so we expect the quality of the graphene being produced to increase significantly further.

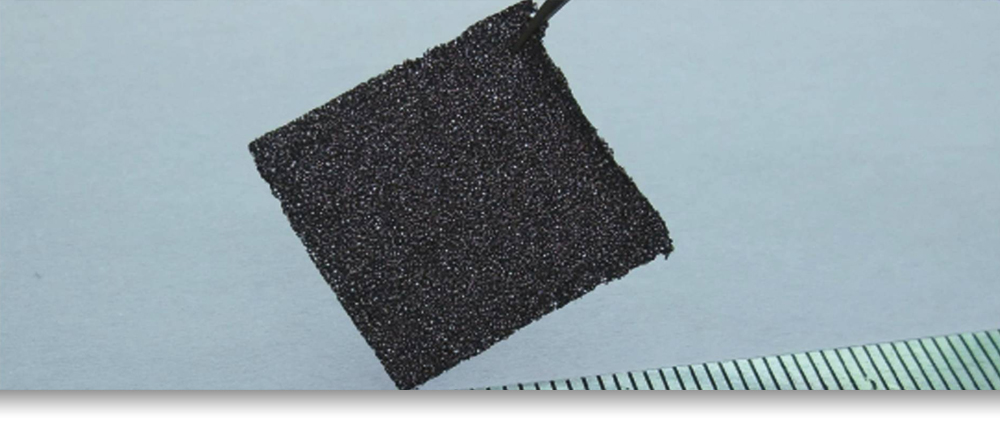

Sapporo Molecular Layered Carbon have experimented with many varieties of polycrystalline substrates to provide the foil upon which the graphene is deposited, including nickel, palladium, platinum and iridium based foils. However we have developed a polycrystalline copper foil that has produced exceptional material in terms of the uniform deposition of single layered graphene of an extremely high quality over large areas.

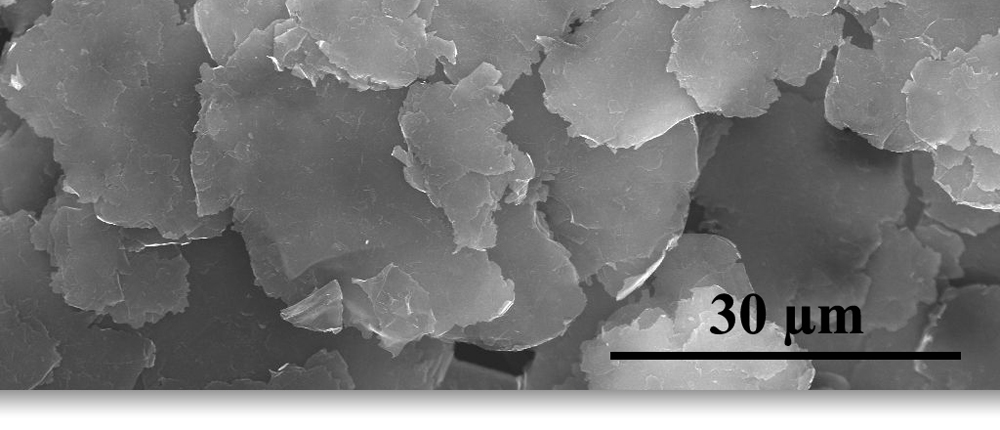

Detailed spectroscopic and imaging analysis have shown that this process results in over 98% of the copper foils surface being covered in a single layer of high quality graphene, with the remaining 2% of the copper foil being covered in a dual or triple layer of graphene. This process is very straightforward meaning that large areas of high quality graphene are readily accessible. These results, in addition to the fact that copper is readily available and inexpensive, makes this process very appealing for the manufacture of graphene.

Aside:

Chemical Vapor Deposition (CVD) is a chemical process used to manufacture high purity solid materials that can perform to very high levels. The process is common in the semiconductor industry in the production of thin films and is now the simplest process available for the preparation of large amounts of high quality graphene.

The process involves the evaporation of carbon atoms into a gaseous state, which are then deposited onto a solid material, a substrate surface (wafer or foil) to produce the desired material.